- Manual Cleaning Dust Collector

- Self-cleaning Dust Collector

- Explosion-proof Dust Collector

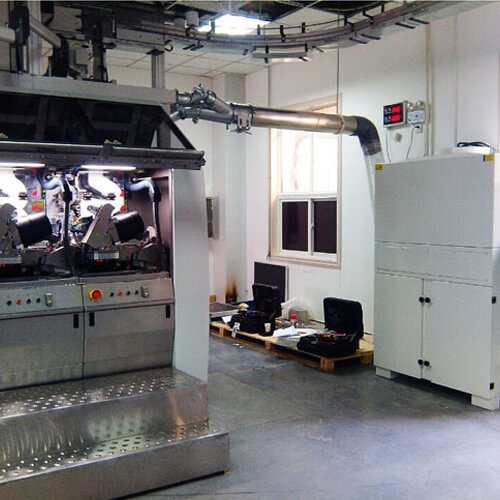

- Central Dust Collector

- Compact & Economic Vacuum Cleaners

- Heavy Duty Vacuum Cleaners

- Wet & Dry Vacuum Cleaners

- Industrial HEPA Vacuum Cleaner

- Explosion-proof Vacuum Cleaner

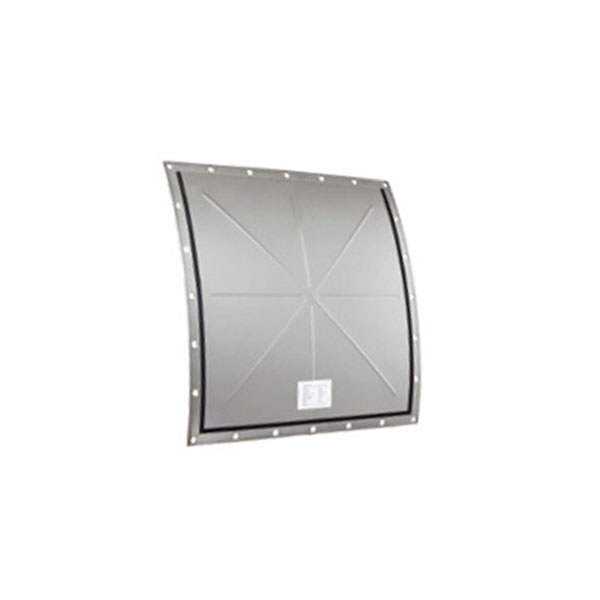

- Explosion Venting Panel

- Flameless Explosion Venting Device

- Explosion Isolation Valve

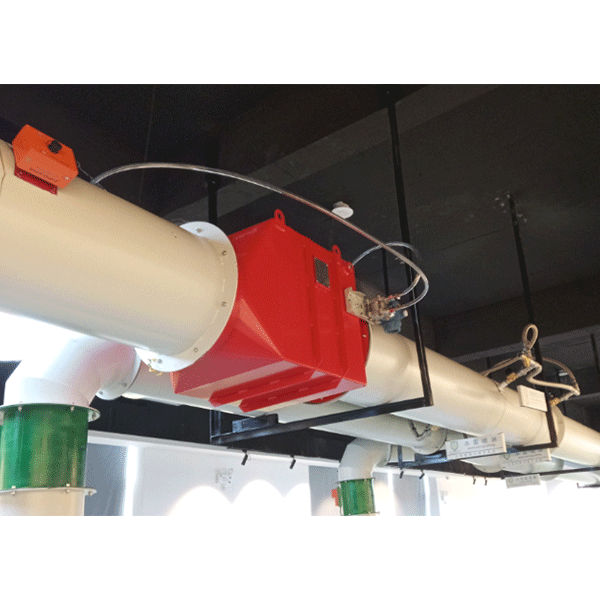

- Spark Detection And Extinguishing System

- Explosion Suppression System

- Explosion Isolation Pinch Valve

What are you looking for?

EN

EN

ja

ja  ko

ko  fr

fr  de

de  ru

ru