Dust Removal Solutions In Laser Cutting

Why People Need Laser Dust Collector

Laser cutting process

A non-traditional thermal process that utilizes light energy from the laser to remove the material by vaporization and ablation.

Exposure risks of laser dust & fumes

The dust and fumes generated during the laser cutting process can be a serious health hazard.

A high-speed laser cutting process can convert metal into airborne particles in a short period, and since the machine works very fast, a large amount of dust and fumes can be generated in no time.

These dust particles are usually of sub-micron size and can be easily inhaled and absorbed into the body

The dust can also affect the cutting efficiency and can diffuse the laser beam. A proper filtration system such as a laser vacuum cleaner should be installed to reduce the hazardous effects of laser cutting.

Solutions for Laser Cutting Dust

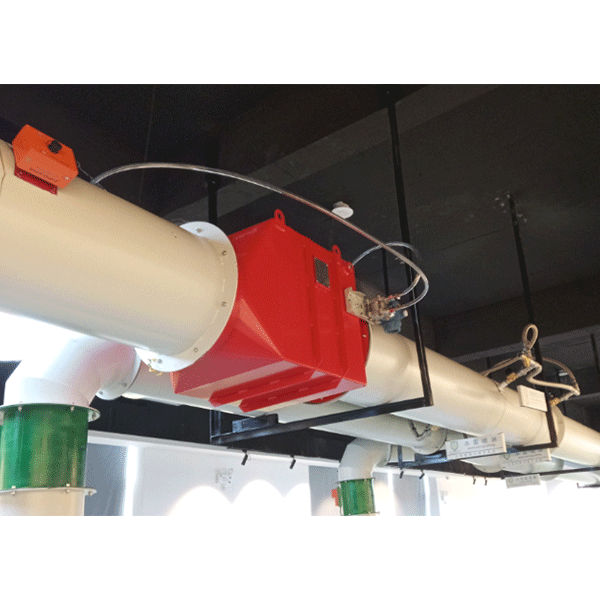

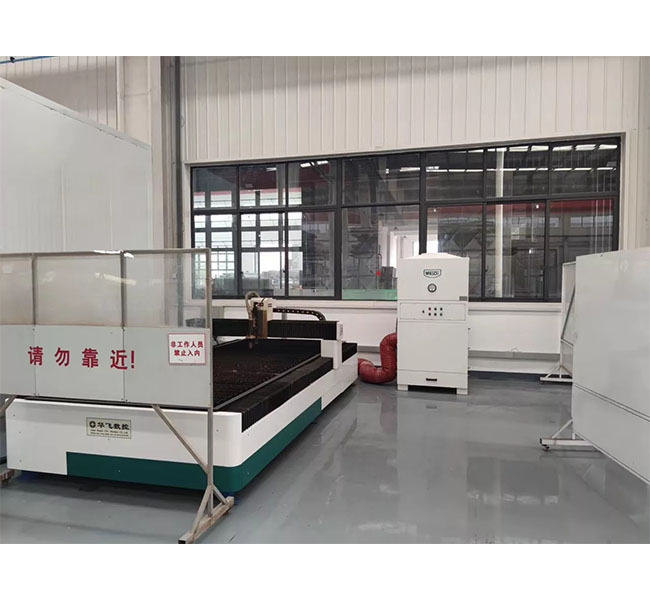

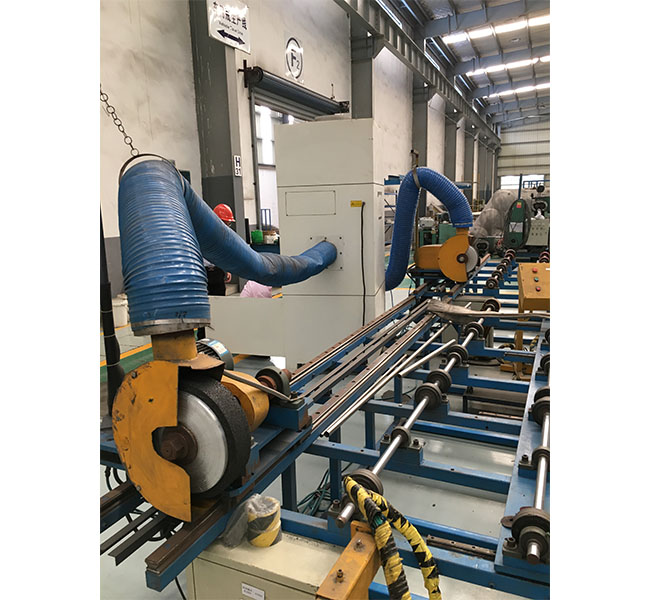

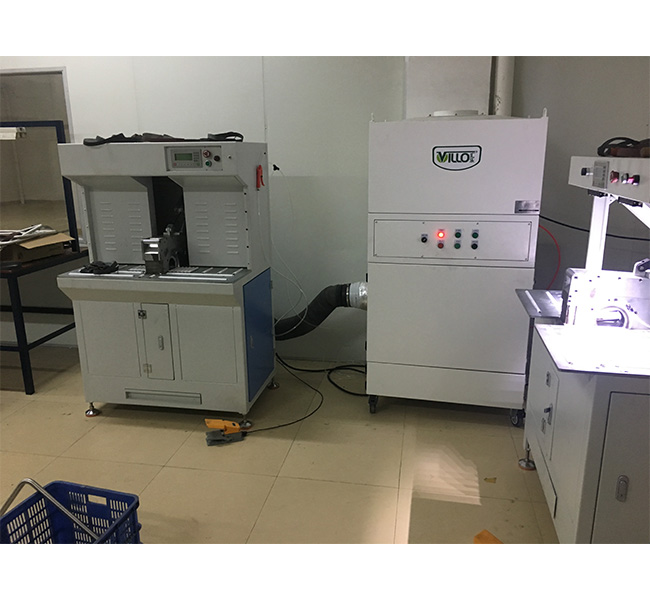

Villo's VJF and VN series dust collectors understand the laser cutting process and how to deal with its harmful side effects, they are designed to be a good industrial fume extractor.

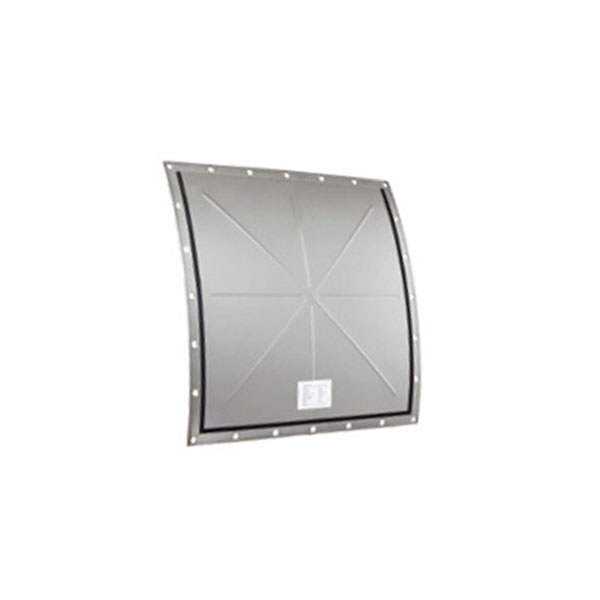

Vacuum cleaner for metal chips are equipped with a high-efficiency PTFE coated filter cartridge and pulse back-blowing dust cleaning device to effectively extract fumes and dust, and can also automatically clean the filter element to ensure dust collection.

For your information:

Laser cutting machine with 3015 or 3030, VJF-5.5 is the best option.

Laser cutting machine with 4020, VJF-7.5 can support well.

Laser cutting machine with 6030, VJF-11 can fit it well.

Laser cutting machine with 8040, Please contact us to match with the most suitable model

For more details about industrial vacuum cleaner for metal chips, please contact us directly.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  ru

ru